Silicon

Shaping

As

silicon is a hard, brittle material, the most suitable materials for shaping

and cutting silicon are the following.

·

Industrial-grade

diamonds

·

SiC and Al2O3

Shaping

Operations involves the following:

·

Removing the seed and

tang ends from the ingots

·

Surface grinding

which defines the diameter of the material.

·

After diameter

grinding one or more flats are ground along the length of the ingot. The larger

flat is called "primary" flat. Purpose of primary flat (a) it is used

as a mechanical locator in automated processing equipment to position the

wafer. (b) Serves to orient the IC device relative to the crystal. Other

smaller flats are called "secondary" flats. Purposes of secondary

flat (a) identify the orientation and conductivity type of the material. (b)

Provide a means of quickly sorting and identifying wafers should mixing occur.

Fig. 9 Standard flat orientations for

different semiconductor wafers [4]

After

removal of seed and tang ends from the ingot, surface grinding and grounding

flats the ingot is ready to be sliced into wafers.

Slicing

determines four wafer parameters:

·

surface orientation

·

thickness

·

taper

·

bow

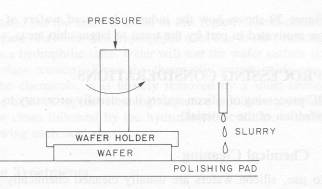

Polishing is the last step and it

is done to obtain a smooth, specular surface on which device features can be

photoengraved [2]. The aim is to produce a surface with a high degree of

surface flatness and minimum local slope to meet the requirements of optical

projection lithography. Typical values of surface flatness are between 5 and 10

microns. In the chemical mechanical polishing (CMP) process, the wafer is held

on a rotating holder and pressed on a rotating polishing pad, with slurry and

water in between. The slurry is a colloidal suspension of fine silica particles

with diameters of about 100°A in an aqueous solution of sodium hydroxide [3]. Sodium hydroxide

oxidizes the silicon surface (chemical process) with the help of heat generated

by the friction between the wafer and polishing pad. Then the silica particles

abrade the silicon oxide away from the surface (mechanical process). Figure [2]

below gives a schematic of the CMP process.

A schematic of CMP process[2].